Every pair of glasses tells a story...

A story that has many different chapters and characters: our brands, creative teams, researchers, and prototype, production and development departments.All the collections made by Marcolin undergo a rigorous technical and quality control process to offer eyewear with a unique design and a perfect fit, while ensuring the highest quality standards. This process, which speaks of passion and excellence, turns an idea into a unique experience thanks to different areas of expertise, which are all essential to create a product that is admired and sought after worldwide: Made in Marcolin eyewear, Seen Everywhere.

Read more Read less-

IDEAS

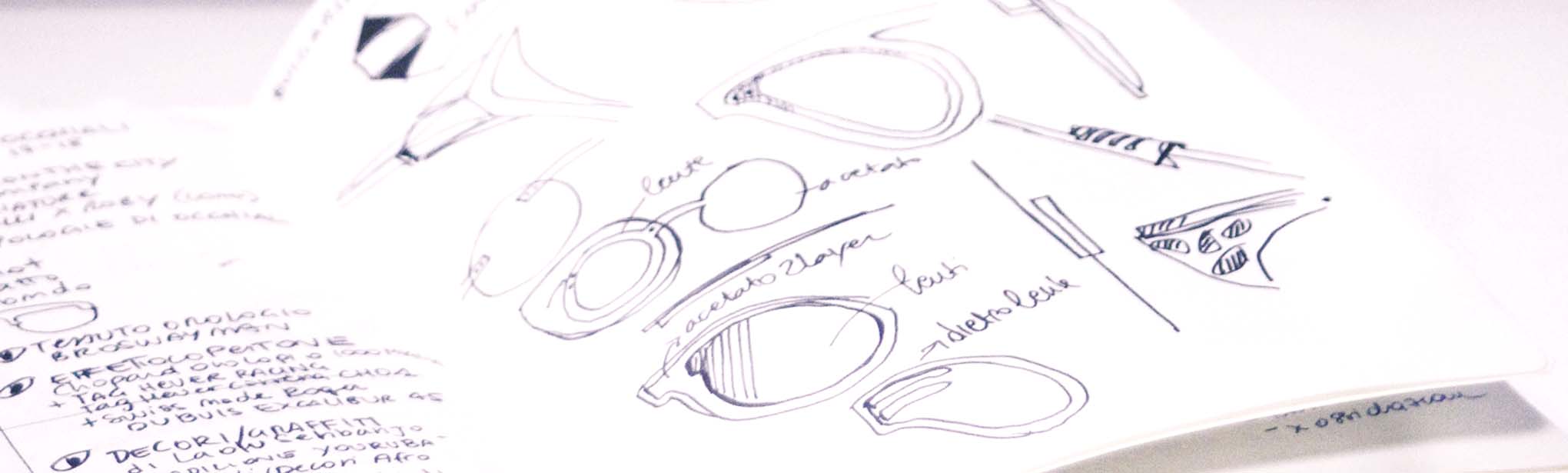

Creativity is the main character in this story: ideas are the starting point for the development of each and every new design. The Marcolin creative team and license brands have a common goal: to create cutting-edge products that anticipate the latest trends and always reinterpret them in an innovative way. We draw inspiration from the world of fashion, design and architecture and from anything that can unleash our creativity.

-

DESIGN

The design phase is a key step in achieving a result that reflects each brand’s style and iconic elements. Also in this phase, the Marcolin creative team collaborates closely with the license brands. After having developed a variety of suggestions and proposals, we reach, together, a result that expresses manufacturing excellence and that, thanks to our inherent vocation for trends and their evolution, paves the way for the creation of prototypes.

-

PROTOTYPES

In this phase, artisans work with the utmost precision and attention to detail. The real prototype phase starts after having created the first design of the frame, which is called “sketch” in technical jargon, and the prototype development team makes a physical object for every new product designed. The result of this process is an initial collection of frames.

-

MATERIALS AND COLORS

Many different materials are used in the collections based on customer requests and specific design needs and on whether a certain material can be used for a certain manufacturing technique that is required to make a frame. Every season, our designers work together with the license brands on fine metal, plastic and bio-based materials to identify the colors, color depth and combinations that best interpret the latest trends and anticipate the aesthetic of tomorrow.

-

MANUFACTURING

Making a pair of glasses requires sixty different manufacturing phases, which are carried out by different workers.

Thanks to the skillful craftsmanship of our expert artisans and technicians, each and every detail becomes a distinctive element of the eyewear produced.

Every corporate department has cutting-edge technological equipment: automated and semi-automated precision machining and milling centers for eyewear fronts, lenses and components.

To make sure that the work cycle and end products meet quality controls across every single step, Marcolin divides its production into three different processes: metal frames, acetate frames and finishes.

-

FINISHING

The final phase in eyewear making is the finishing phase. Skillful human craftsmanship meets hi-tech machinery to define the features of every style, adding meticulous details and customizing the shapes and frames.

-

ADJUSTMENT

In the last phase of the entire process, the fit is adjusted. All the components of the optical frames and sunglasses, from the surfaces to the lenses, are checked piece by piece and their key features are guaranteed, starting from their fit.

-

YOUR EYEWEAR

Lastly, every single piece is arranged to be sold and placed in each brand’s specific packaging.

Your experience with your new eyewear begins now.